EV ENERGY SOLUTIONS

Powering the future with the right people.

As electrification accelerates, the great race is on for securing top talent in the Battery Industry.

What We Know

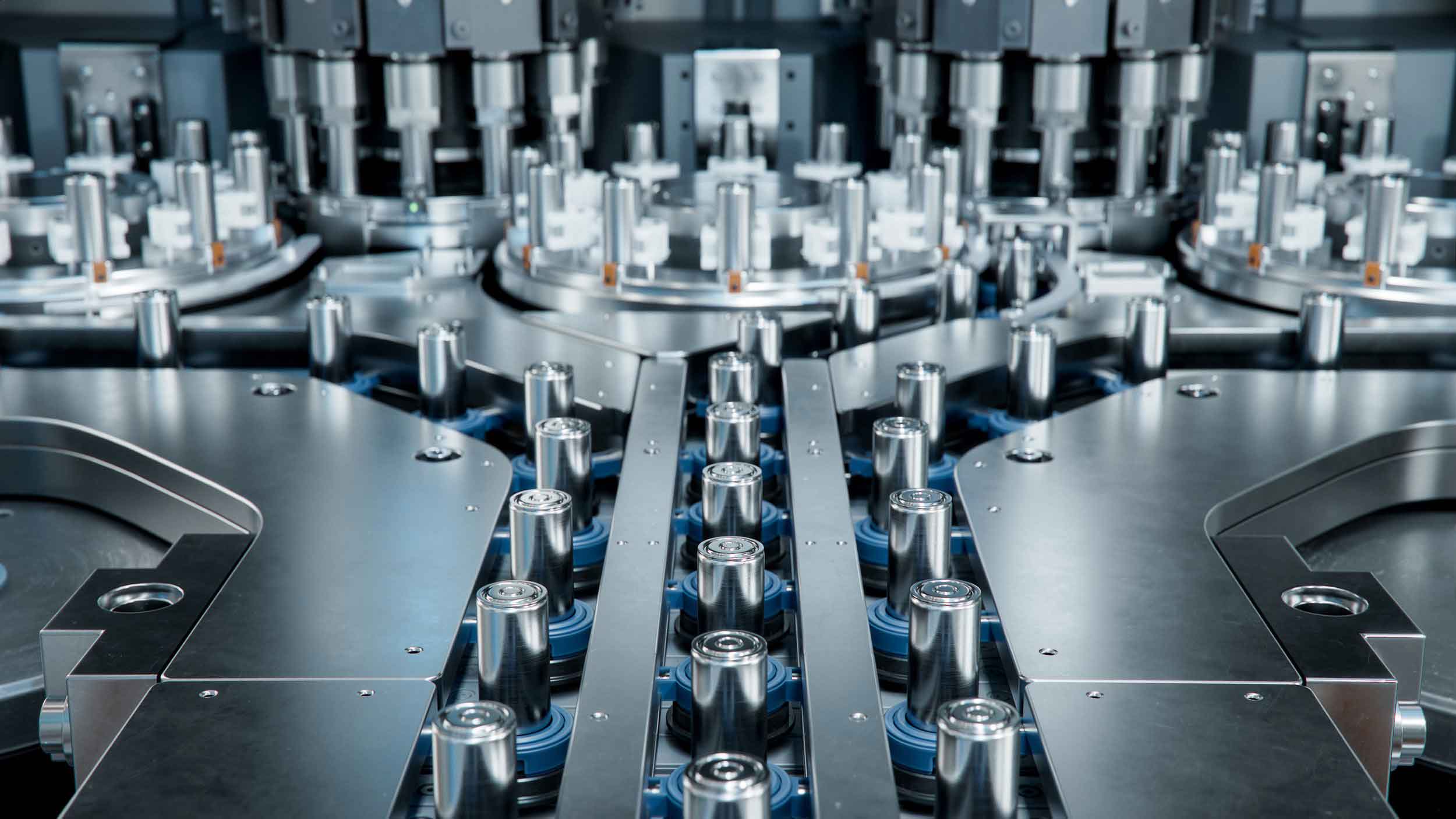

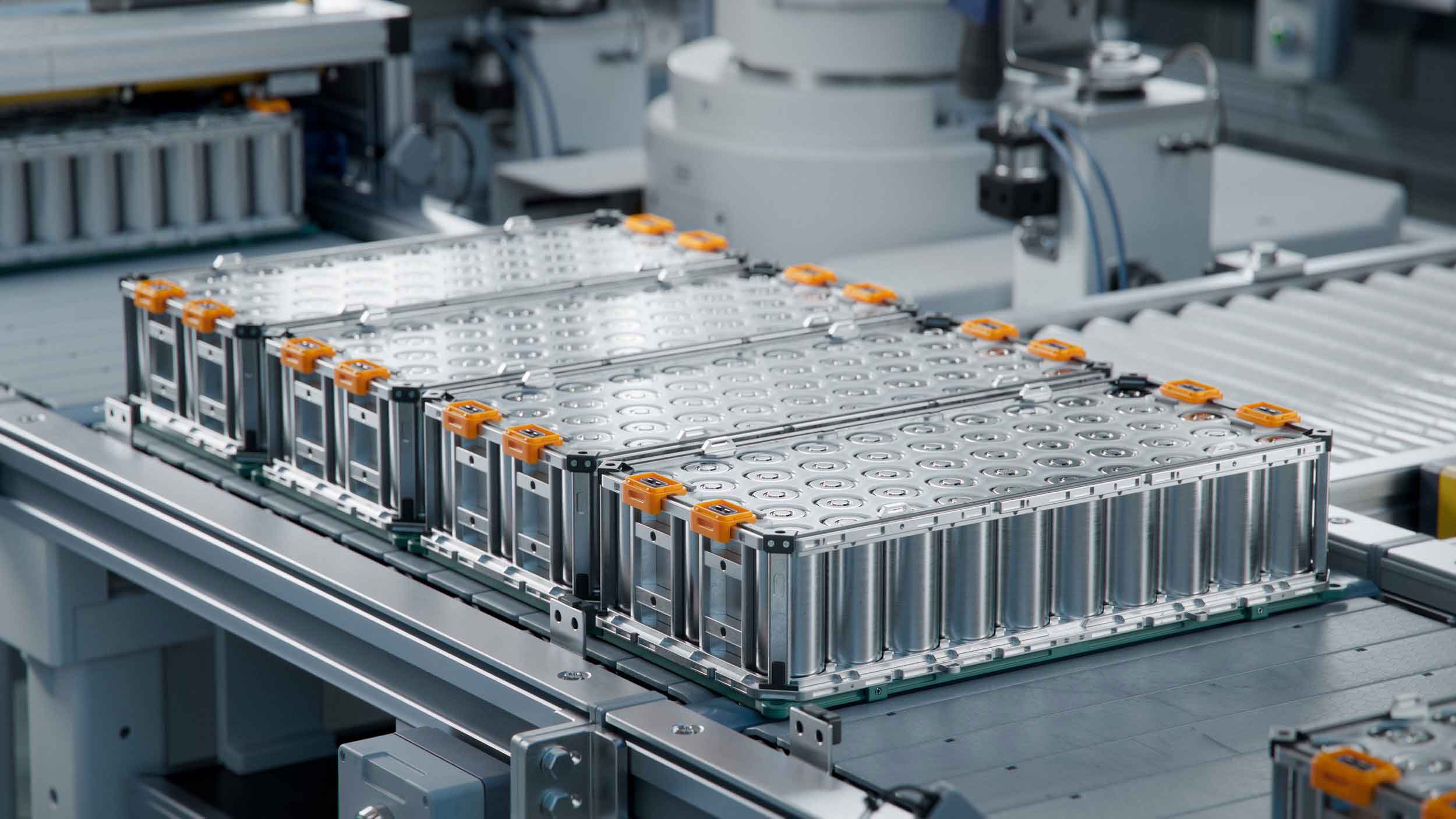

EV battery manufacturing combines the use of advanced technology and automation, to improve the optimal use of rare metals and other mined and processed materials. The quality of the end product relies heavily on the design of the battery structure which includes cells, modules, and the overall battery pack.

Engineering and Automation

Automation and advanced manufacturing processes are becoming increasingly significant. Staffing services with an extensive background in automation, robotics, and engineering can radically enhance efficiency and productivity.

Scalability

Efficiently scaling up production is often vital. Companies that can achieve effective economies of scale in battery manufacturing, will often achieve better cost efficiency.

As the demand for EV batteries increase, we are the staffing service most capable of providing scalable solutions, to meet challenging production needs. Whether it involves ramping up, or sizing down the workforce.

OUR TOP 4 AREAS OF EXPERTISE

Adaptability

Innovative Thinking

Data-Driven

Attention to Detail

Safety & Quality Control

As EV battery production is often subject to strict quality and safety regulations, your staffing partner should also prioritize candidates with the strongest track record in quality control and safety. Which will ensure the highest standards of reliability and safety of the batteries produced.